Viper RF provides a range of services for full design and testing of MMIC and module solutions.

Custom MMIC Design

VIPER RF provides custom designed MMICs and module solutions for Clients. An approach using custom designed MMICs can offer significant system performance improvements compared to a configuration of standard parts.

With our extensive knowledge of microwave and millimetre-wave MMIC technologies, we work alongside our Clients to identify the optimum technical and commercial solution for each challenge.

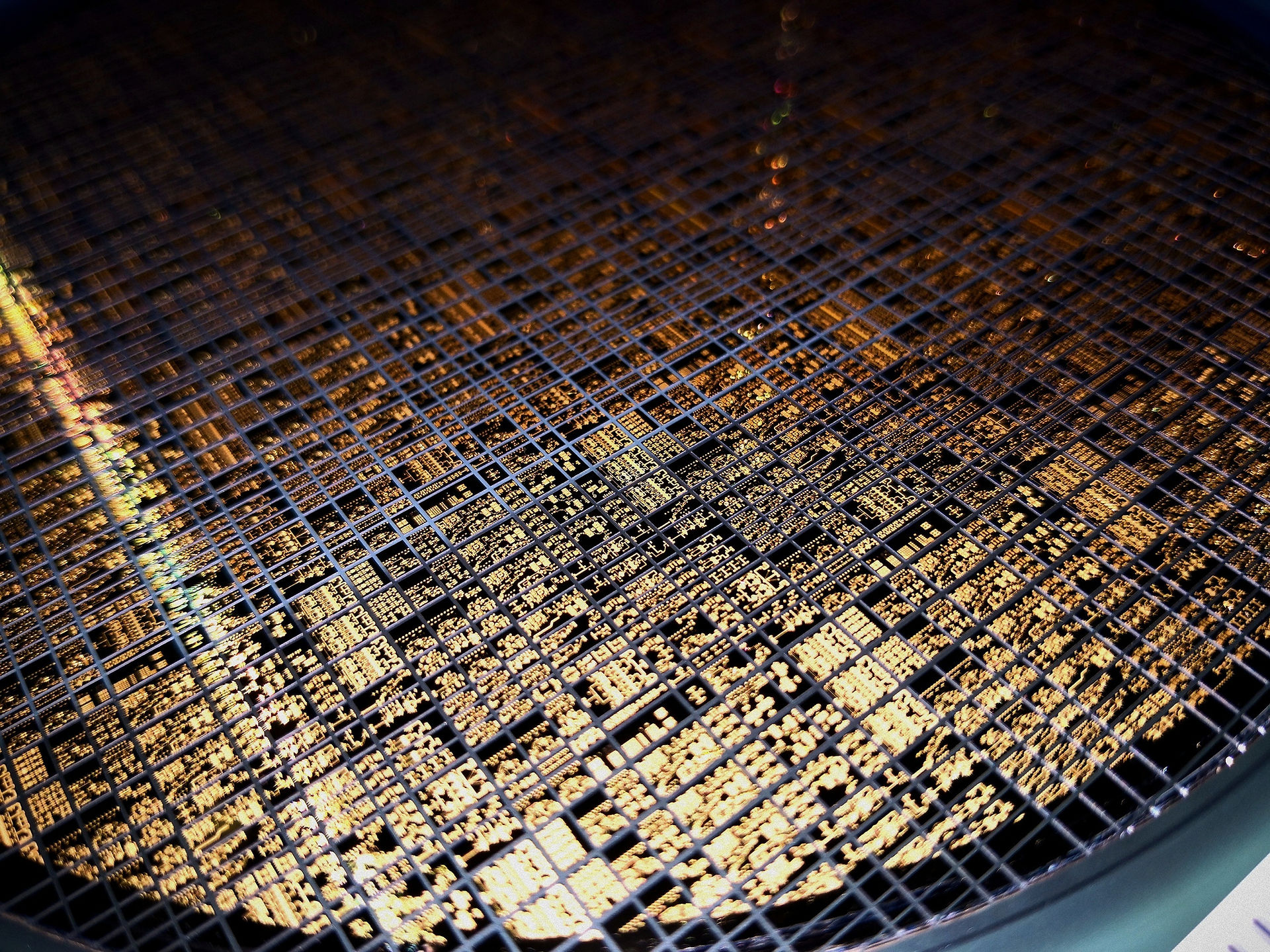

For production, VIPER RF has capabilities to test wafers and packaged parts in our class 10 000 cleanroom, and links to off-shore packaging test houses to cater for high volumes.

Designed on cutting edge technologies

Model development & EM-Simulation

Thermal Simulation

RF Module Design

Viper RF works alongside clients to design module based solutions. Utilising a combination of custom MMIC designs and COTS components to provide optimal cost-performance for clients.

In house assembly of prototype modules allows rapid product development.

RF Module Prototyping

Full Enclosure Design

Integration of Custom and COTS parts.

High Frequency RF Testing

Inside our class 10000 cleanroom, Viper RF has the ability to test packaged parts and RF modules, alongside full RF on wafer testing.

Automatic wafer prober with test capabilities up to 110GHz enables 100% RF testing in production.

Thermal chambers allows Viper RF to verify device performance and stability over a wide temperature range.

Class 10000 Cleanroom

100% RF On Wafer Testing

-50 to 150C Test Capabilites